Aerospace PCBA refers to the assembly of circuit boards used in the aerospace industry. Due to the high reliability and maintainability requirements of circuit boards in the aerospace field, the design, manufacturing and testing of aerospace PCBA need to strictly comply with relevant standards and specifications.

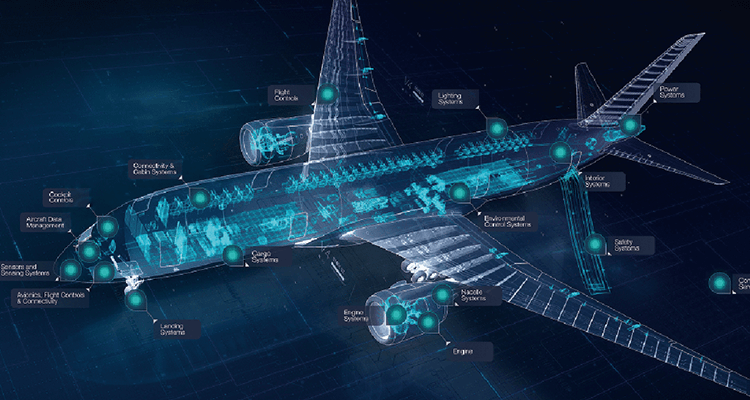

PCBA applicable to the aerospace sector mainly includes the following categories:

Flight control circuit board: It is the most core circuit board in the flight control system, which converts various data of aerospace flight into control signals, and plays a key role in flight safety.

Aeronautical communication circuit board: It is one of the core circuit boards in the aeronautical communication system and is used to process various aeronautical communication signals.

Power management circuit board: It completes the integration of the power management system, which can provide a stable and reliable power supply for the aircraft, and control the use and transmission of electric energy.

Air pressure measurement circuit board: It is one of the core components to measure the altitude and speed of the aircraft, with high precision and high reliability requirements.

Photoelectric control circuit board: It is mainly used in aircraft optical systems, including telescopic drones and laser weapons.

Aerospace PCBA needs to meet the requirements of high reliability, anti-interference ability, high temperature and low temperature adaptability, aircraft weight requirements, etc. In addition, it is necessary to comply with the standards and specifications in the aerospace field, such as the MIL-PRF-55110 standard and IPC-A-610 standard.

Aerospace PCBA needs to meet the requirements of high reliability, anti-interference ability, high temperature and low temperature adaptability, aircraft weight requirements, etc. In addition, it is necessary to comply with the standards and specifications in the aerospace field, such as the MIL-PRF-55110 standard and IPC-A-610 standard.