China Double-side PCB Assembly OEM Manufacturing Electronic Component Sourcing PCBA Fabrication Turn-key Service

|

Turnkey PCBA |

PCB+components sourcing+assembly+package+shipment |

|

Assembly details |

SMT and Thru-hole, ISO SMT and DIP lines |

|

Lead Time |

Prototype: 15 work days. Mass order: 20~25 work days |

|

Testing on products |

Flying Probe Test, X-ray Inspection, AOI Test, Functional test |

|

Quantity |

Min quantity: 1pcs. Prototype, small order, mass order, all OK |

|

Files needed |

PCB: Gerber files(CAM, PCB, PCBDOC) Components: Bill of Materials(BOM list) Assembly: Pick-N-Place file |

|

PCB Panel Size |

Min size: 0.25*0.25 inches(6*6mm) Max size: 20*20 inches(500*500mm) |

|

PCB Solder Type |

Water Soluble Solder Paste, RoHS lead free |

|

Components details |

Passive Down to 0201 size BGA and VFBGA Leadless Chip Carriers/CSP Double-sided SMT Assembly Fine Pitch to 0.8mils BGA Repair and Reball Part Removal and Replacement |

|

Component package |

Cut Tape,Tube,Reels,Loose Parts |

Send us Gerber/PCB file, PCB specifications, BOM list and special assembly requirement so we will quote you the best PCBA prices within 1-3 days

PCB Bare Board:

Multi-layer,FR4,Metal,Creamic,Rogers,FPC,HDI board.

HASL,Immersion Gold/silver/Au,OSP, etc.

PCB Assembly:

9 Testing Procedures,100% Functional Tested.

BGA with X-Ray and Lead Free Assembly.

Components Sourcing:

15 Years Purchasing Experience.

Multi-channel Component Supply.

Finished products assembly:

Functional test/Programing.

Conformal Coating. Burning test.

Gift Box Packing. Storege Service.

OEM project advantages:

1. Strong engineering group

2. Efficient and simple One-stop Turnkey Service

3. Full supply chain to guarantee EB,PP&MP time

4. Design and material cost down

ODM project advantages:

1. Professional R&D team to support customers’ requirements

2. Design software platforms

3. Experienced project management

4. No MOQ and quick delivery

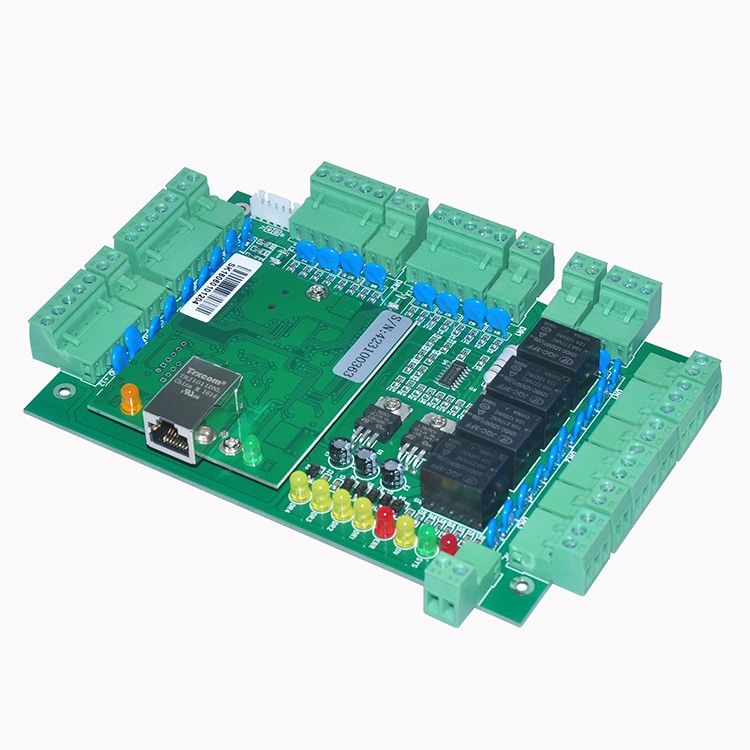

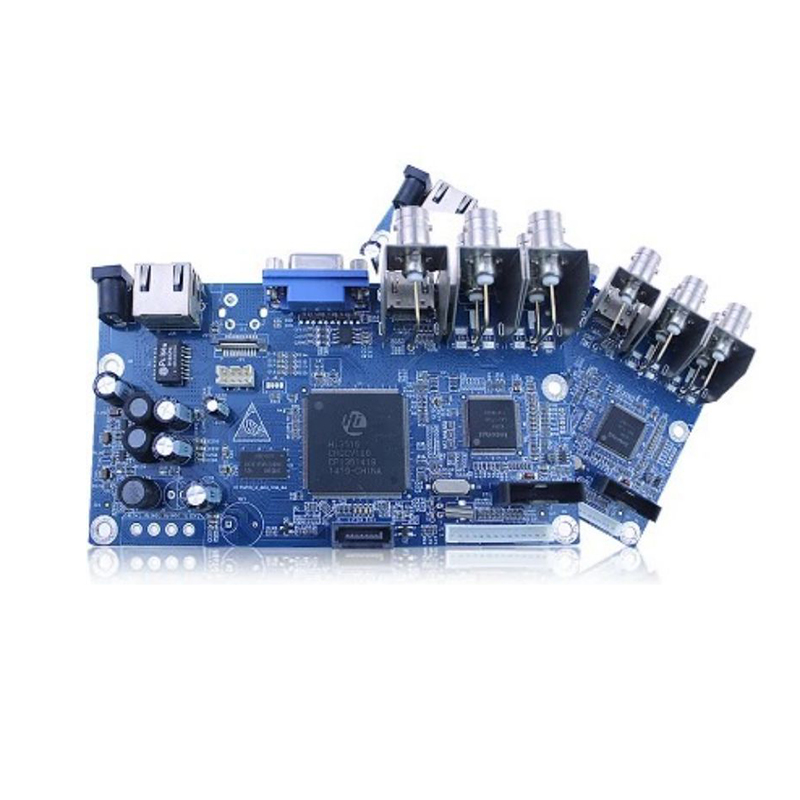

OEM products:

Millions of circuit boards are produced here every year, which provides superior service for automotive electronics, medical electronics, power communications, industrial automation, intelligent home and other industries around the world.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Skype

-

Skype