Knee massager temperature controller pcb assembly PCB multilayer laminating services pcba oem

Files and Requirment for PCBA quotation:

A BOM (Bill of Materials) with reference designators: component description, manufacturer's name and part number.

PCB Gerber files.

A PCB fabrication drawing and PCBA assembly drawing.

PCBA Test procedures.

Any PCBA mechanical restrictions such as assembly height requirements

PCB board manufacture and PCBA design service:

PCB board made, circuit board parts purchased by us

PCBA Electronic testing circuit board

PCBA fast delivery, anti-static package

RoHS Directive-compliant, lead-free

One stop PCBA service from PCB design, PCB layout, PCB manufacture, components purchasing, PCB assembly, test, packing and PCBA delivery

PCBA Technical requirement:

Professional PCBA surface-mounting and through-hole soldering technology

Various sizes like 1206, 0805, 0603 components SMT technology

PCBA ICT (In Circuit Test), FCT (Functional Circuit Test) technology

PCB assembly with UL, CE, FCC, RoHS approval

Nitrogen gas reflow soldering technology for SMT

High standard PCBA SMT and solder assembly line

High density interconnected board placement technology capacity

PCBA Quote requirement:

PCB Gerber file and PCBA Bom list

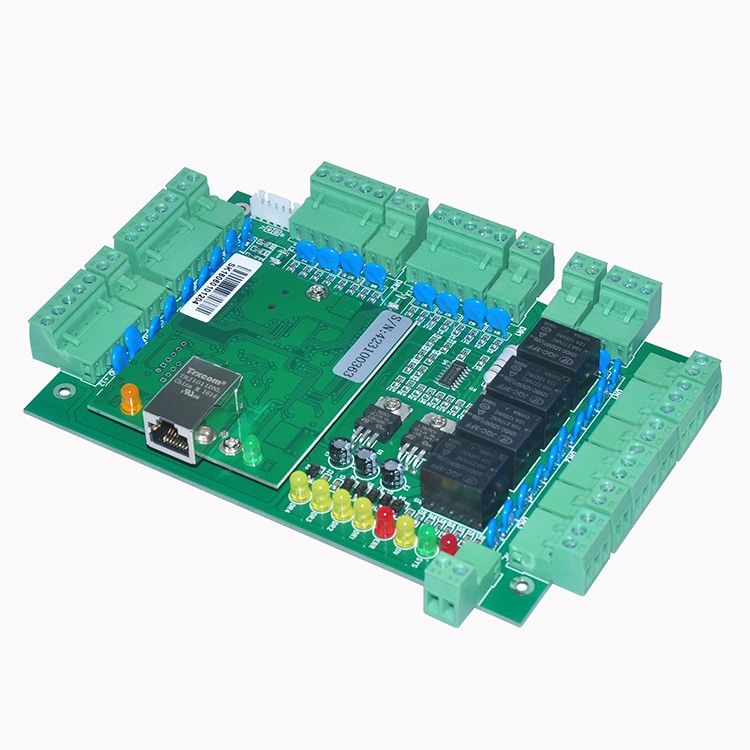

Clear pics of pcba or pcba sample for us

PCBA Test method

PCBA Outer packing: standard carton packing

PCBA Hole tolerance: PTH: ±0.076, NTPH: ±0.05

PCBA Certificate: UL, ISO 9001, ISO 14001, RoHS,UL

PCB Profiling punching: routing, V-cut, beveling

Providing PCBA OEM service to all sorts of printed circuit board assembly

Over 10 Years experience in PCB & PCB Assembly and Box-build in housing

1、Strong PCBA R&D team, 5 engineers with more than 6 years of PCBA experience in electronic products

2、The PCBA factory is 2000 square meters with 100 employees.

3、Daily output of patch 1 million points, plug-in 200,000 points, finished PCBA product assembly and test 5,000 points.

4、With a large number of PCBA production equipment:PCB High speed SMT machine,PCB high precision multi-function SMT machine, PCB automatic printing machine, semi-automatic printing machine, hot air reflow welding, etc.

5、We have a perfect PCBA quality control system,manage the process from component purchase, warehousing to product shipment to ensure product quality.

Turnkey PCBA PCB make +components sourcing+pcb assembly+pcba package

Assembly details PCBA SMT and Thru-hole, ISO SMT and DIP lines

Lead Time PCBA Prototype: 15 work days. Mass order: 20~25 work days

Testing on products Flying Probe Test, X-ray Inspection, AOI Test, Functional test

Quantity Min quantity: 1pcs. Prototype, small order, mass order, all OK

Files needed PCB: Gerber files(CAM, PCB, PCBDOC)

Components: Bill of Materials(PCBA BOM list)

PCB Assembly: Pick-N-Place file

PCB Panel Size PCB Min size: 0.25*0.25 inches(6*6mm)PCB Max size: 20*20 inches(500*500mm)

PCB Solder Type Water Soluble Solder Paste, RoHS lead free

Components details Passive Down to 0201 size

BGA and VFBGA

Leadless Chip Carriers/CSP

Double-sided SMT Assembly

Fine Pitch to 0.8mils

BGA Repair and Reball

Part Removal and Replacement

Component package Cut Tape,Tube,Reels,Loose Parts

PCB assembly

process Drilling-----Exposure-----Plating-----Etaching & Stripping-----Punching-----Electrical Testing-----SMT-----Wave Soldering-----Assembling-----ICT-----Function Testing-----Temperature & Humidity Testing

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Skype

-

Skype