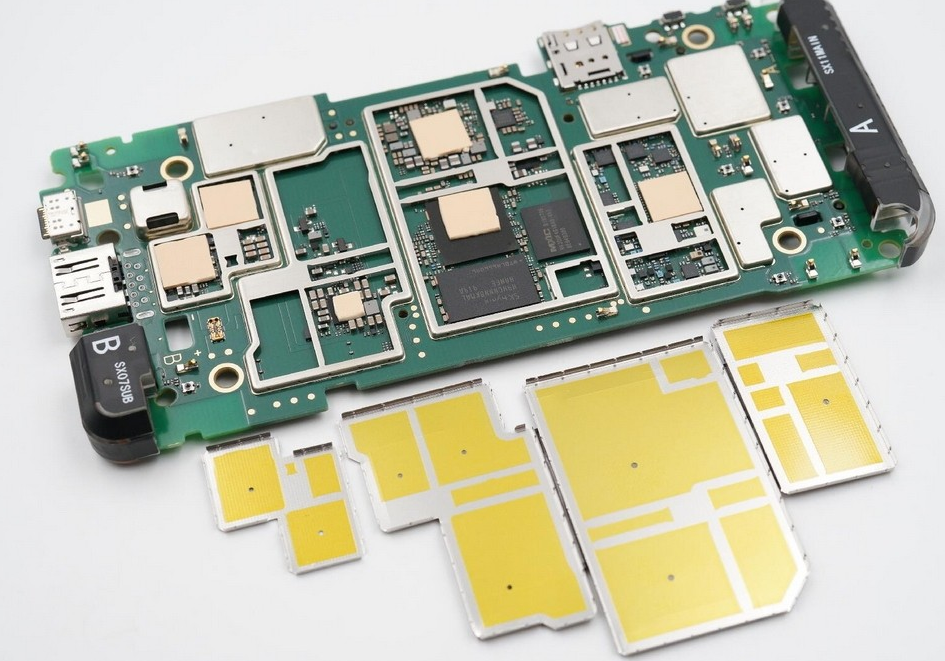

We can see shielding on many PCBS, especially in consumer electronics such as mobile phones. The phone’s PCB is covered with shields.

Shielding covers are mainly found in mobile phone PCBS, mainly because mobile phones have a variety of wireless communication circuits, such as GPS, BT, WiFi, 2G/3G/4G/5G, and some sensitive analog circuits and DC-DC switching power circuits usually need to be isolated with shielding covers. On the one hand, they do not affect other circuits, and on the other hand, they prevent other circuits from affecting themselves.

This is one of the functions of protecting against electromagnetic interference; Another function of the shield is to prevent collisions. PCB SMT will be divided into multiple boards. Usually, adjacent plates need to be separated to prevent a near collision during subsequent testing or other transportation.

The raw materials of the shield are generally white copper, stainless steel, tinplate, etc. At present, most of the shields are used in white copper.

White copper is characterized by a slightly poor shielding effect, softer, more expensive than stainless steel, easy to tin; Stainless steel shielding effect is good, high strength, moderate price; However, it is difficult to tin (it can hardly be tin without surface treatment, and it is improved after nickel plating, but it is still not conducive to the patch); The tinplate shielding effect is the worst, but the tin is good and the price is cheap.

The shield can be divided into fixed and detachable.

Single-piece Shielding cover fixed is generally called single-piece, directly SMT attached to the PCB, English generally called Shielding Frame.

The detachable two-piece shield is also commonly called the two-piece shield, and the two-piece shield can be opened directly without the help of a heat gun tool. The price is more expensive than a single piece, the SMT is welded on the PCB, called Shielding Frame, the above is called Shielding Cover, directly on the Shielding Frame, easy to disassemble, generally the following Frame is called shielding frame, the above Cover is called shielding cover. Frame is recommended to use white copper, tin is better; Cover can be made of tinplate, mainly cheap. Two-piece can be used in the early stage of the project to facilitate debugging, wait for hardware debugging stability, and then consider the use of single-piece to reduce costs.

Post time: Mar-13-2024