Many kinds of production raw materials are used in SMT patch processing. The tinnote is the more important one. The quality of the tin paste will directly affect the welding quality of the SMT patch processing. Choose different types of tinnuts. Let me briefly introduce the common tin paste classification:

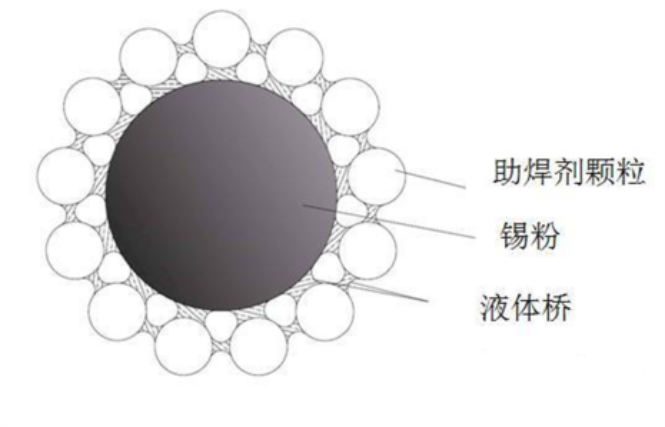

Weld paste is a kind of pulp to mix the weld powder with a paste -like welding agent (rosin, diluent, stabilizer, etc.) with a welded function. In terms of weight, 80 ~ 90%are metal alloys. In terms of volume, metal and solder accounted for 50%.

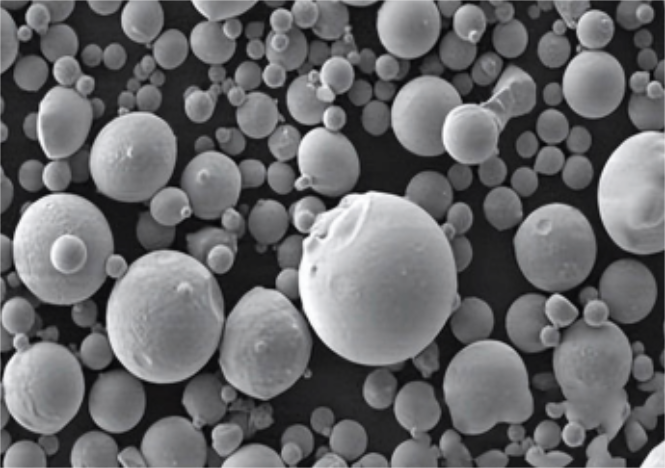

Figure 3 Ten paste granules (SEM) (left)

Figure 4 Specific diagram of tin powder surface cover (right)

The solder paste is the carrier of tin powder particles. It supplies the most suitable flow degeneration and humidity to promote heat transmission to the SMT area and reduce the surface tension of the liquid on the weld. Different ingredients show different functions:

① Solvent:

The solvent of this ingredient weld ingredient has a uniform adjustment of automatic adjustment in the operation process of tin paste, which has a greater impact on the life of the weld paste.

② Resin:

It plays an important role in increasing the adhesion of tin paste and to repair and prevent PCB from re -oxidation after welding. This basic ingredient has a vital role in the fixation of parts.

③ Activant:

It plays the role of removing the oxidized substances of the PCB copper film surface layer and part SMT patch site, and has the effect of reducing the surface tension of tin and lead liquid.

④ Tentacle:

Automatic adjustment of the viscosity of the weld paste plays an important role in printing to prevent the tail and adhesion.

First, according to the composition of the solder paste classification

1, lead solder paste: contains lead components, greater harm to the environment and the human body, but the welding effect is good, and the cost is low, can be applied to some electronic products without environmental protection requirements.

2, lead-free solder paste: environmentally friendly ingredients, little harm, used in environmentally friendly electronic products, with the improvement of national environmental requirements, lead-free technology in the smt processing industry will become a trend.

Second, according to the melting point of the solder paste classification

Generally speaking, the melting point of solder paste can be divided into high temperature, medium temperature and low temperature.

The commonly used high temperature is Sn-Ag-Cu 305,0307; Sn-Bi-Ag was found in the medium temperature. Sn-Bi is commonly used at low temperatures. In the SMT patch processing need to be selected according to different product characteristics.

Three, according to the fineness of tin powder division

According to the particle diameter of the tin powder, the tin paste can be divided into 1, 2, 3, 4, 5, 6 grades of powder, of which 3, 4, 5 powder is the most commonly used. The more sophisticated the product, the tin powder selection needs to be smaller, but the smaller the tin powder, the corresponding oxidation area of the tin powder will increase, and the round tin powder helps to improve the printing quality.

No. 3 powder: The price is relatively cheap, commonly used in large smt processes;

No. 4 powder: commonly used in tight foot IC, smt chip processing;

No. 5 powder: Often used in very precise welding components, mobile phones, tablets and other demanding products; The more difficult the smt patch processing product is, the more important the choice of solder paste is, and the choice of suitable solder paste for the product helps to improve the smt patch processing process.

Post time: Jul-05-2023