The cost of energy storage system is mainly composed of batteries and energy storage inverters. The total of the two constitutes 80%of the cost of electrochemical energy storage system, of which the energy storage inverter accounts for 20%. The IGBT insulating grid bipolar crystal is the upstream raw material of the energy storage inverter. The performance of IGBT determines the performance of the energy storage inverter, accounting for 20%-30%of the value of the inverter.

The main role of IGBT in the field of energy storage is transformer, frequency conversion, intervolution conversion, etc., which is an indispensable device in energy storage applications.

Figure: IGBT module

The upstream raw materials of energy storage variables include IGBT, capacitance, resistance, electric resistance, PCB, etc. Among them, IGBT still mainly depends on imports. There is still a gap between domestic IGBT at the technology level and the world’s leading level. However, with the rapid development of China’s energy storage industry, the domesticization process of IGBT is also expected to accelerate.

IGBT energy storage application value

Compared with photovoltaic, the value of energy storage IGBT is relatively high. Energy storage uses more IGBT and SIC, involving two links: DCDC and DCAC, including two solutions, namely the optical storage integrated and separate energy storage system. The independent energy storage system, the amount of power semiconductor devices is about 1.5 times the photovoltaic. At present, optical storage may account for more than 60-70%, and a separate energy storage system accounts for 30%.

Figure: BYD IGBT module

IGBT has a wide range of application layers, which is more advantageous than MOSFET in the energy storage inverter. In actual projects, IGBT has gradually replaced MOSFET as the core device of photovoltaic inverters and wind power generation. The rapid development of the new energy power generation industry will become a new driving force for the IGBT industry.

IGBT is the core device for energy transformation and transmission

IGBT can be fully understood as a transistor that controls electronic two -way (multi -directional) flowing with valve control.

IGBT is a composite full -control voltage -driven power semiconductor device composed of the BJT bipolar triode and insulating grid field effect tube. The advantages of two aspects of pressure drop.

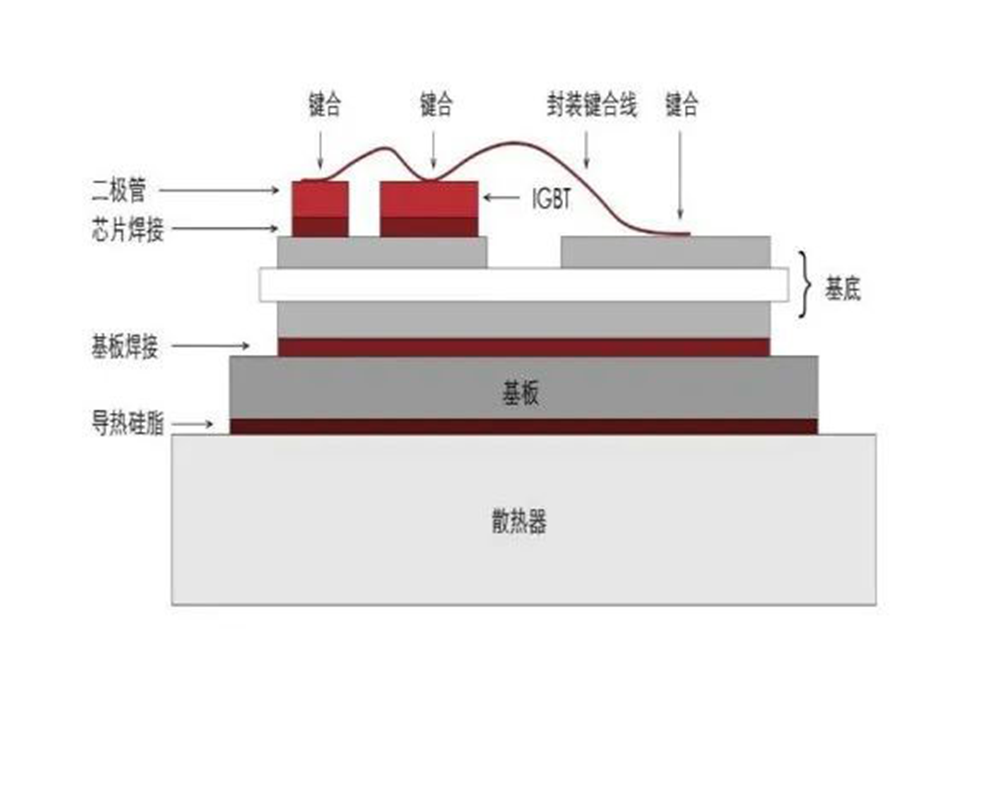

Figure: IGBT module structure schematic diagram

The switch function of IGBT is to form a channel by adding positive to the gate voltage to provide the base current to the PNP transistor to drive IGBT. Conversely, add the inverse door voltage to eliminate the channel, flow through the reverse base current, and turn the IGBT off. The driving method of IGBT is basically the same as that of MOSFET. It only needs to control the input pole N one -channel MOSFET, so it has high input impedance characteristics.

IGBT is the core device of energy transformation and transmission. It is commonly known as the “CPU” of electrical electronic devices. As a national strategic emerging industry, it has been widely used in new energy equipment and other fields.

IGBT has many advantages including high input impedance, low control power, simple driving circuit, fast switching speed, large -state current, reduced diversion pressure, and small loss. Therefore, it has absolute advantages in the current market environment.

Therefore, IGBT has become the most mainstream of the current power semiconductor market. It is widely used in many areas such as new energy power generation, electric vehicles and charging piles, electrified ships, DC transmission, energy storage, industrial electrical control and energy saving.

Figure: Infineon IGBT module

IGBT classification

According to the different product structure, IGBT has three types: single -pipe, IGBT module and smart power module IPM.

(Charging piles) and other fields (mostly such modular products sold in the current market). The intelligent power module IPM is mainly widely used in the field of white home appliances such as inverter air conditioners and frequency conversion washing machines.

Depending on the voltage of the application scenario, IGBT has types such as ultra -low voltage, low voltage, medium voltage and high voltage.

Among them, the IGBT used by new energy vehicles, industrial control, and household appliances is mainly medium voltage, while rail transit, new energy power generation and smart grids have higher voltage requirements, mainly using high -voltage IGBT.

IGBT mostly appears in the form of modules. IHS data shows that the proportion of modules and single tube is 3: 1. The module is a modular semiconductor product made by the IGBT chip and the FWD (continuing diode chip) through a customized circuit bridge, and through plastic frames, substrates and substrates, etc.

Market situation:

Chinese companies are growing rapidly, and they are currently dependent on imports

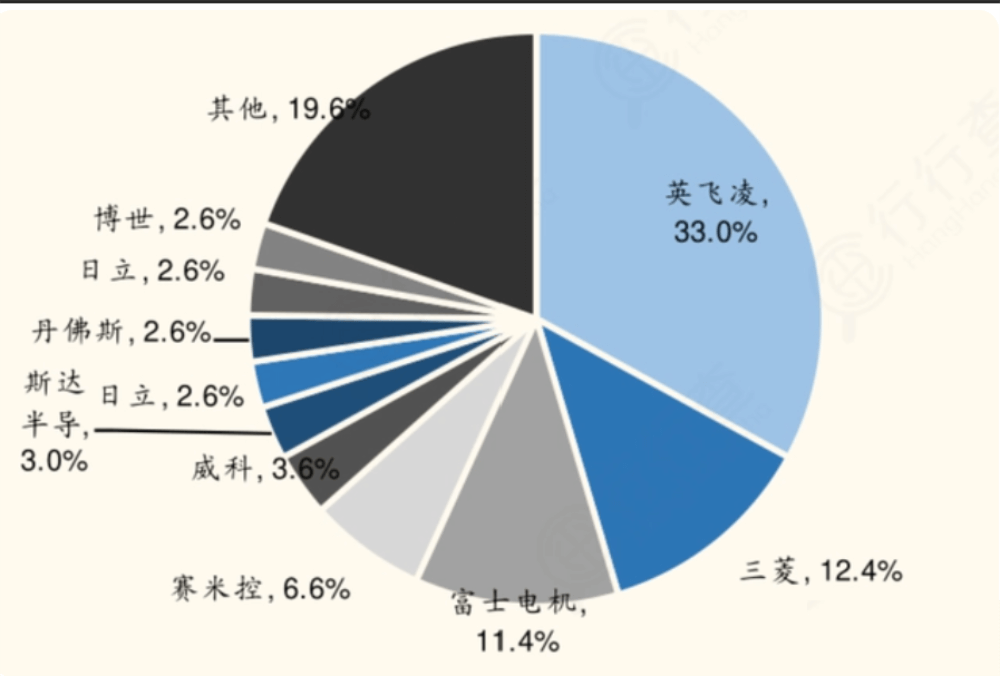

In 2022, my country’s IGBT industry had an output of 41 million, with a demand of about 156 million, and a self -sufficient rate of 26.3%. At present, the domestic IGBT market is mainly occupied by overseas manufacturers such as Yingfei Ling, Mitsubishi Motor, and Fuji Electric, of which the highest proportion is Yingfei Ling, which is 15.9%.

The IGBT module market CR3 reached 56.91%, and the total share of domestic manufacturers Star Director and CRRC’s era of 5.01%was 5.01%. The top three manufacturers’ market share of the global IGBT split device reached 53.24%. Domestic manufacturers entered the top ten market share of the global IGBT device with a market share of 3.5%.

IGBT mostly appears in the form of modules. IHS data shows that the proportion of modules and single tube is 3: 1. The module is a modular semiconductor product made by the IGBT chip and the FWD (continuing diode chip) through a customized circuit bridge, and through plastic frames, substrates and substrates, etc.

Market situation:

Chinese companies are growing rapidly, and they are currently dependent on imports

In 2022, my country’s IGBT industry had an output of 41 million, with a demand of about 156 million, and a self -sufficient rate of 26.3%. At present, the domestic IGBT market is mainly occupied by overseas manufacturers such as Yingfei Ling, Mitsubishi Motor, and Fuji Electric, of which the highest proportion is Yingfei Ling, which is 15.9%.

The IGBT module market CR3 reached 56.91%, and the total share of domestic manufacturers Star Director and CRRC’s era of 5.01%was 5.01%. The top three manufacturers’ market share of the global IGBT split device reached 53.24%. Domestic manufacturers entered the top ten market share of the global IGBT device with a market share of 3.5%.

Post time: Jul-08-2023