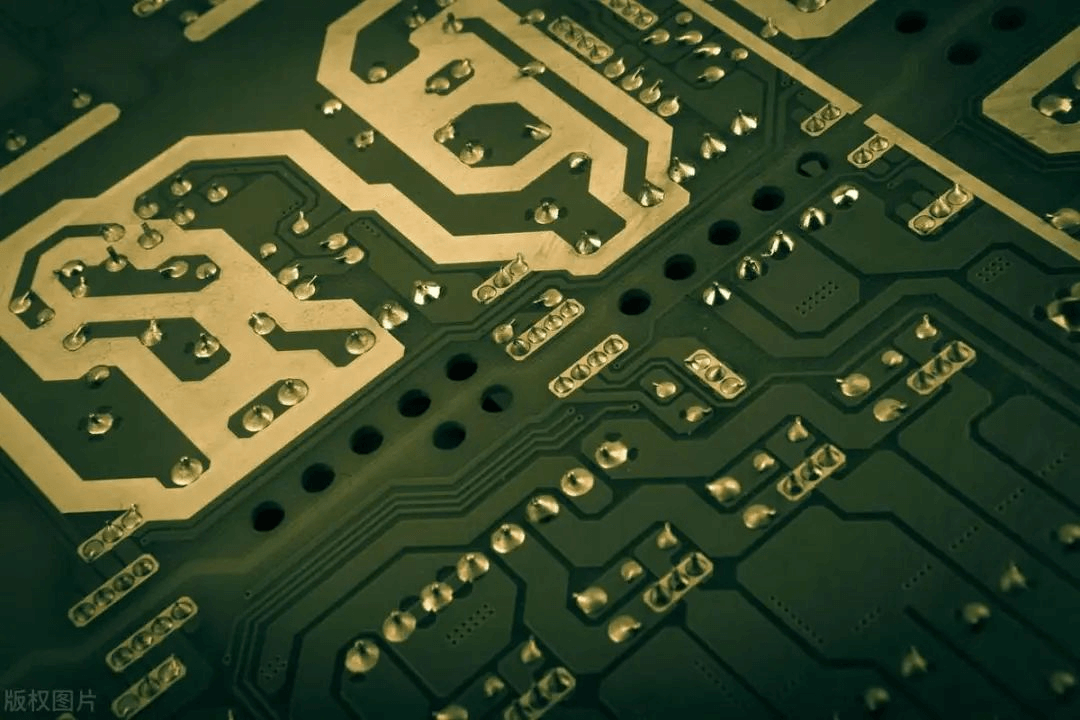

In the PCB circuit board there is a process called PCB electroplating. PCB plating is a process in which a metal coating is applied to a PCB board to enhance its electrical conductivity, corrosion resistance and welding ability.

The ductility test of PCB electroplating is a method to evaluate the reliability and quality of the plating on the PCB board.

PCB electroplating

Ductility test procedure

1. Prepare the test sample: Select a representative PCB sample and ensure that its surface is ready and free of dirt or surface defects.

2. Make a test cut: Make a small cut or scratch on the PCB sample for ductility testing.

3. Perform a tensile test: Place the PCB sample in the appropriate test equipment, such as a stretching machine or a stripping tester. Gradually increasing tension or stripping forces are applied to simulate the stress in the actual use environment.

4. Observation and measurement results: Observe any breakage, cracking or peeling that occurs during the test. Measure parameters related to ductility, such as stretch length, breaking strength, etc.

5. Analysis results: According to the test results, the ductility of PCB coating is evaluated. If the sample withstands the tensile test and remains intact, it indicates that the coating has good ductility.

The above is our collation of the relevant content of pcb electroplating ductility test. The specific methods and standards of PCB electroplating ductility test may vary according to different industries and applications.

Post time: Nov-14-2023