SMT welding causes

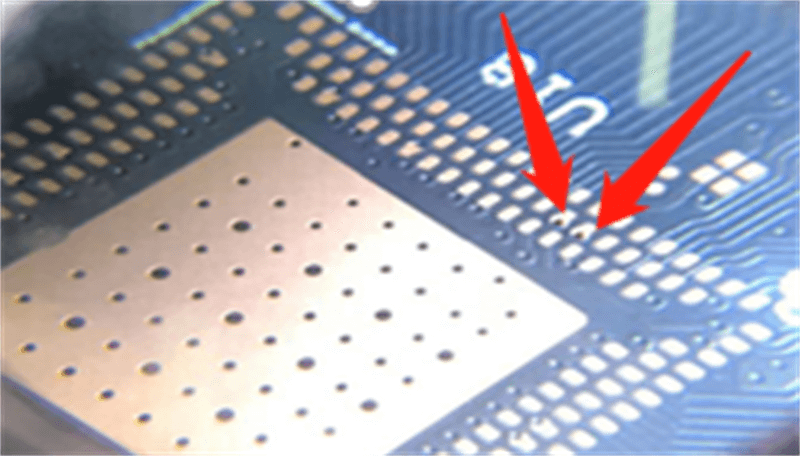

1. PCB pad design defects

In the design process of some PCB, because the space is relatively small, the hole can only be played on the pad, but the solder paste has fluidity, which may penetrate into the hole, resulting in the absence of solder paste in reflow welding, so when the pin is insufficient to eat tin, it will lead to virtual welding.

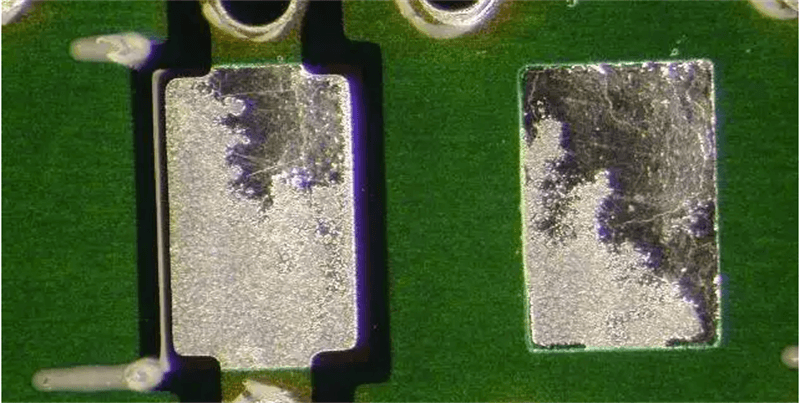

2.Pad surface oxidation

After re-tinning the oxidized pad, reflow welding will lead to virtual welding, so when the pad oxidizes, it needs to be dried first. If the oxidation is serious, it needs to be abandoned.

3.Reflow temperature or high temperature zone time is not enough

After the patch is completed, the temperature is not enough when passing through the reflow preheating zone and the constant temperature zone, resulting in some of the hot melt climbing tin that has not occurred after entering the high temperature reflow zone, resulting in insufficient tin eating of the component pin, resulting in virtual welding.

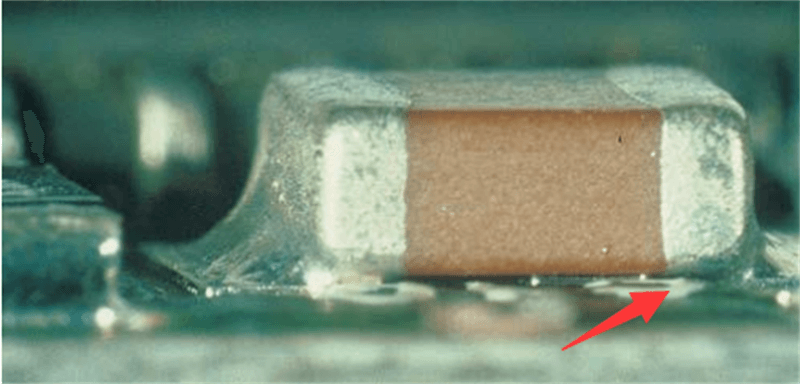

4.Solder paste printing is less

When the solder paste is brushed, it may be due to small openings in the steel mesh and excessive pressure of the printing scraper, resulting in less solder paste printing and rapid volatilization of the solder paste for reflow welding, resulting in virtual welding.

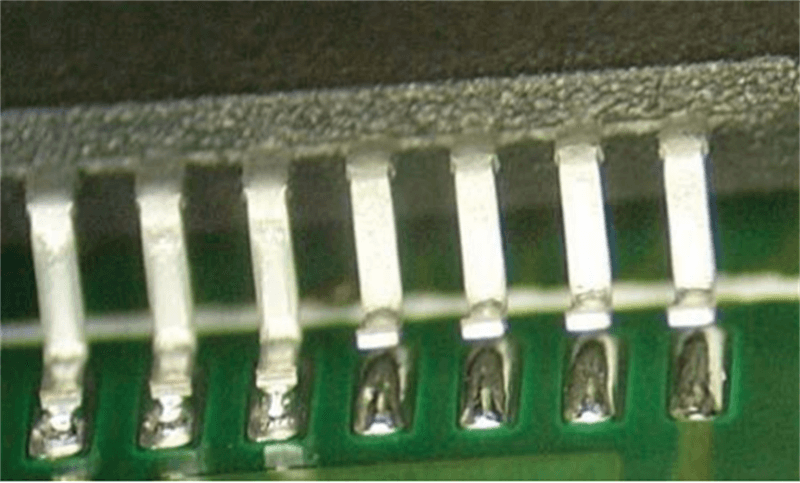

5.High-pin devices

When the high-pin device is SMT, it may be that for some reason, the component is deformed, the PCB board is bent, or the negative pressure of the placement machine is insufficient, resulting in different hot melting of the solder, resulting in virtual welding.

DIP virtual welding reasons

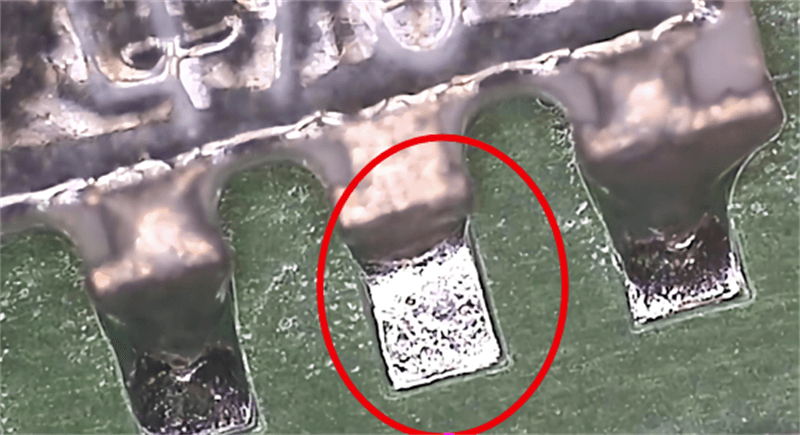

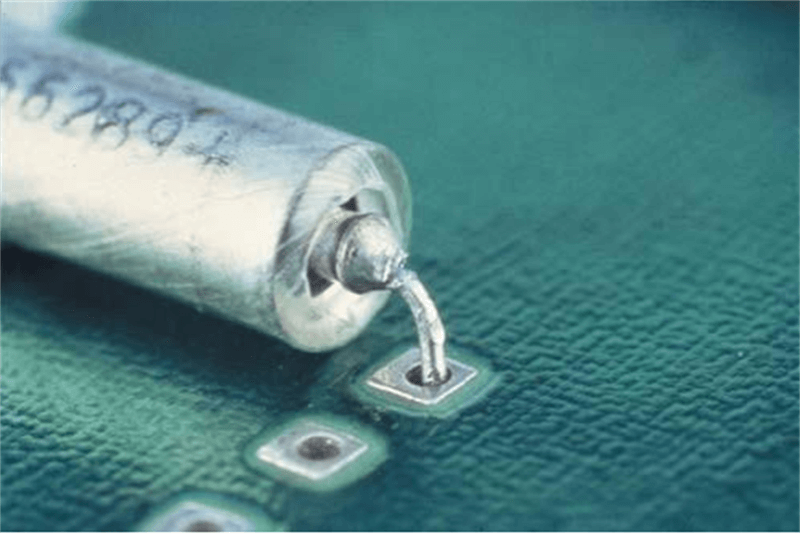

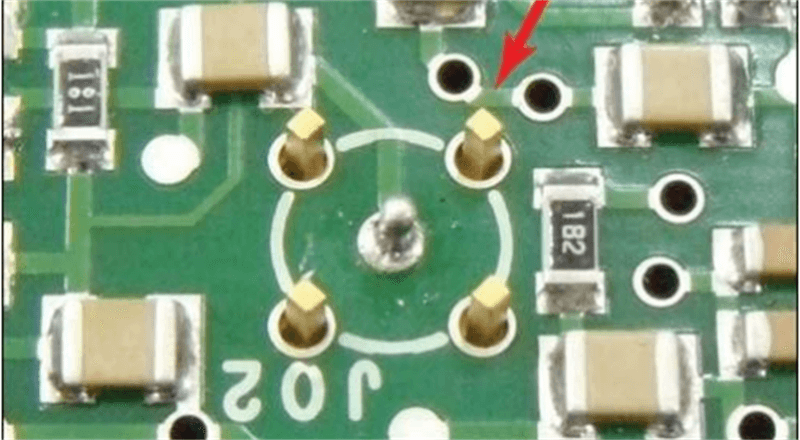

1.PCB plug-in hole design defects

PCB plug-in hole, tolerance is between ±0.075mm, PCB packaging hole is larger than the pin of the physical device, the device will be loose, resulting in insufficient tin, virtual welding or air welding and other quality problems.

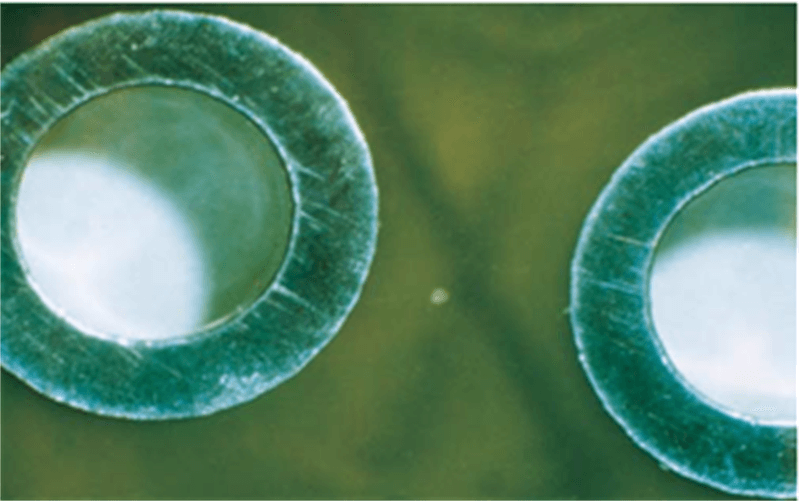

2.Pad and hole oxidation

PCB pad holes are unclean, oxidized, or contaminated with stolen goods, grease, sweat stains, etc., which will lead to poor weldability or even non-weldability, resulting in virtual welding and air welding.

3.PCB board and device quality factors

Purchased PCB boards, components and other solderability is not qualified, no strict acceptance test has been carried out, and there are quality problems such as virtual welding during assembly.

4.PCB board and device expired

Purchased PCB boards and components, due to the inventory period is too long, affected by the warehouse environment, such as temperature, humidity or corrosive gases, resulting in welding phenomena such as virtual welding.

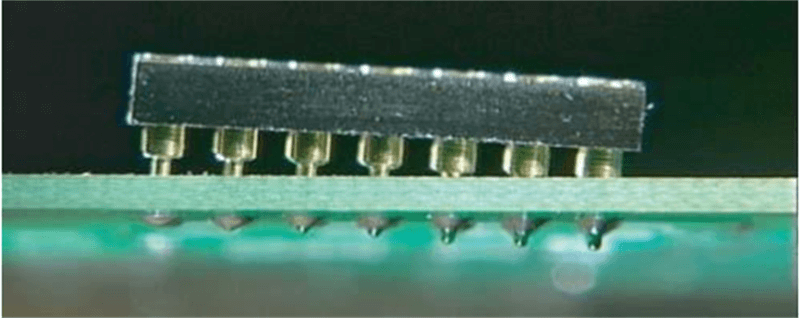

5.Wave soldering equipment factors

The high temperature in the wave welding furnace leads to accelerated oxidation of the solder material and the surface of the base material, resulting in reduced adhesion of the surface to the liquid solder material. Moreover, the high temperature also corrodes the rough surface of the base material, resulting in reduced capillary action and poor diffusivity, resulting in virtual welding.

Post time: Jul-11-2023