In the field of electronics manufacturing, PCB manufacturing and PCB assembly processes play a vital role in the practical application of electronic products. Understanding the differences between these two processes is critical for companies looking for reliable, efficient PCB assembly services. As a leading PCBA supplier and Chinese PCB manufacturer, New Dachang Technology is committed to providing comprehensive product assembly services in China. In this article, we’ll delve into the differences between PCB manufacturing and PCB assembly, clarifying the importance of each in the production of electronic devices.

PCB Manufacturing: The Basics of Electronic Circuits

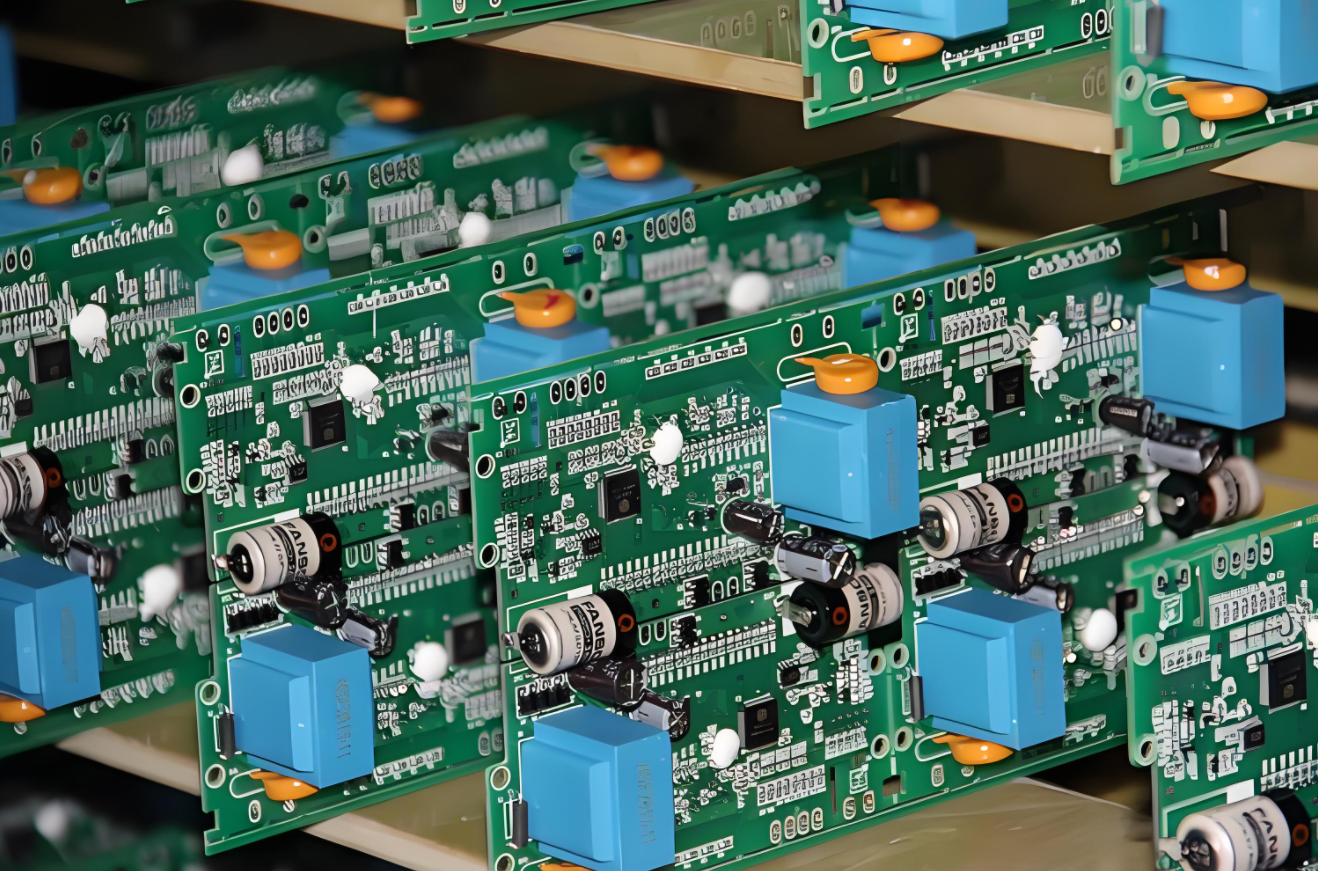

PCB fabrication, also known as PCB fabrication, is the process of creating an exposed printed circuit board before mounting components. This foundational phase involves several key steps, including design verification, material selection, paneling, imaging, etching, drilling and surface preparation. As a well-known PCB manufacturer in China, Xindachang Technology utilizes advanced technology and state-of-the-art facilities to ensure the accuracy and quality of PCB manufacturing.

The process begins with design verification, a thorough review of the PCB layout to identify and correct any potential issues. Once the design is approved, the selected materials are ready for the next phase. Panelization is the arrangement of multiple PCBs on one board to optimize production efficiency. An imaging process then uses photoresist to transfer the circuit pattern to the board, which is then etched to remove excess copper and define the circuit. Drilling is then performed to create holes for component placement and interconnection.

Surface preparation is the final step in PCB manufacturing and involves applying a protective coating to the board to prevent oxidation and ensure solderability. This critical process improves the durability and reliability of the PCB and prepares it for the subsequent stages of PCB assembly.

PCB Assembly: Bringing Components to Life

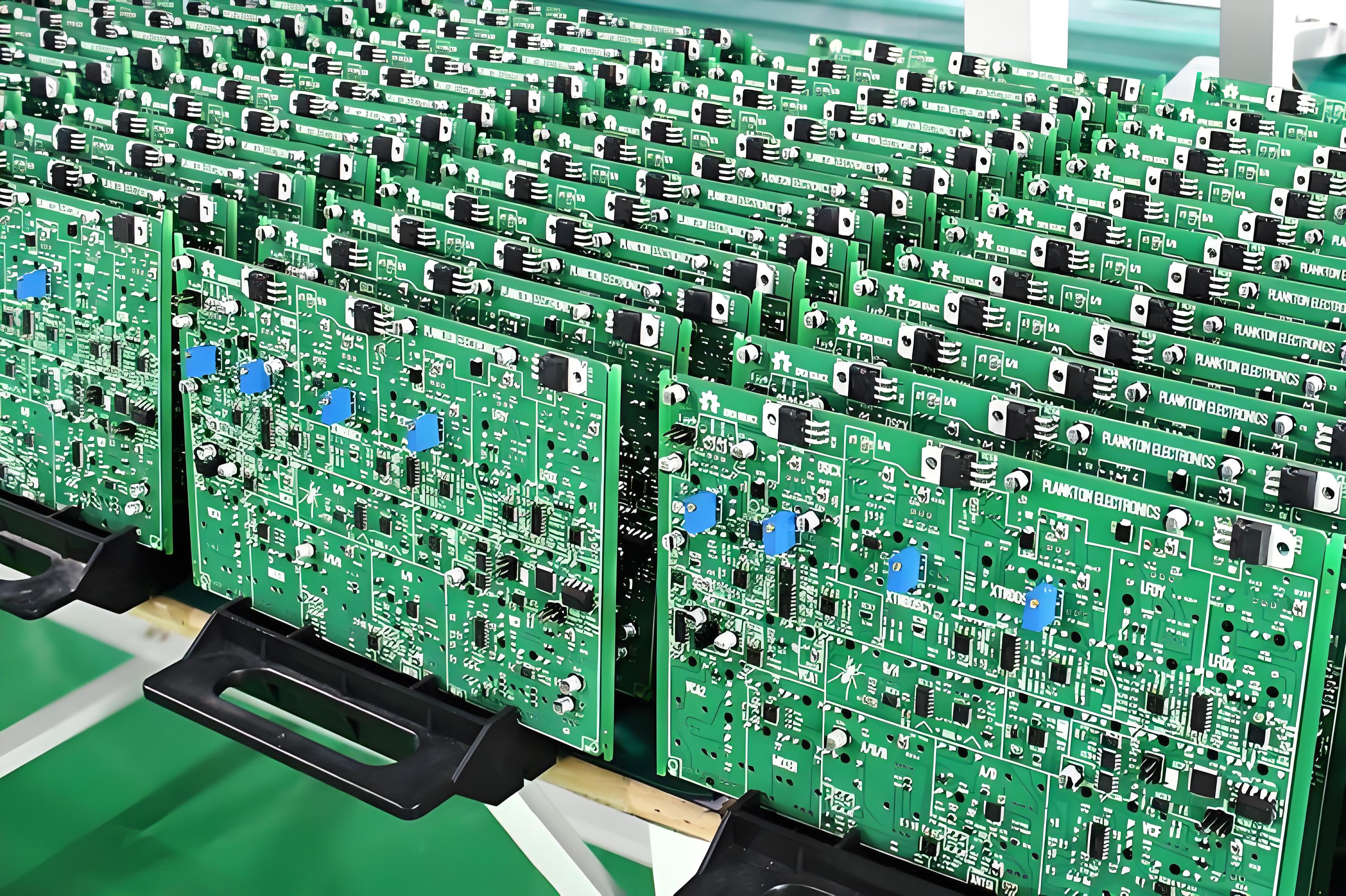

PCB assembly, also known as PCBA (printed circuit board assembly), is the process of mounting electronic components on a manufactured PCB to create a functional circuit board. This complex process involves precise placement, soldering, inspection and testing of components to ensure the integrity and functionality of the assembled PCB. With its rich experience in PCB assembly services, New Dachang Technology provides comprehensive one-stop PCBA services, including component procurement, to simplify the entire assembly process.

The PCB assembly process begins with the procurement of electronic components, and New Dachang Technology’s expertise in component procurement ensures the availability of high-quality assembled parts. Once components are obtained, they undergo rigorous inspection to verify their authenticity and quality. The components are then placed on the PCB using advanced placement machines, ensuring precise positioning and alignment.

Soldering is a critical stage of PCB assembly and involves the use of solder to bond components to the PCB. New Dachang Technology’s advanced facilities and skilled technicians ensure the reliability and consistency of welding processes, adhering to industry standards and best practices. After soldering, the assembled PCB undergoes a thorough inspection, including visual inspection and functional testing, to identify and correct any potential defects.

meaning of difference

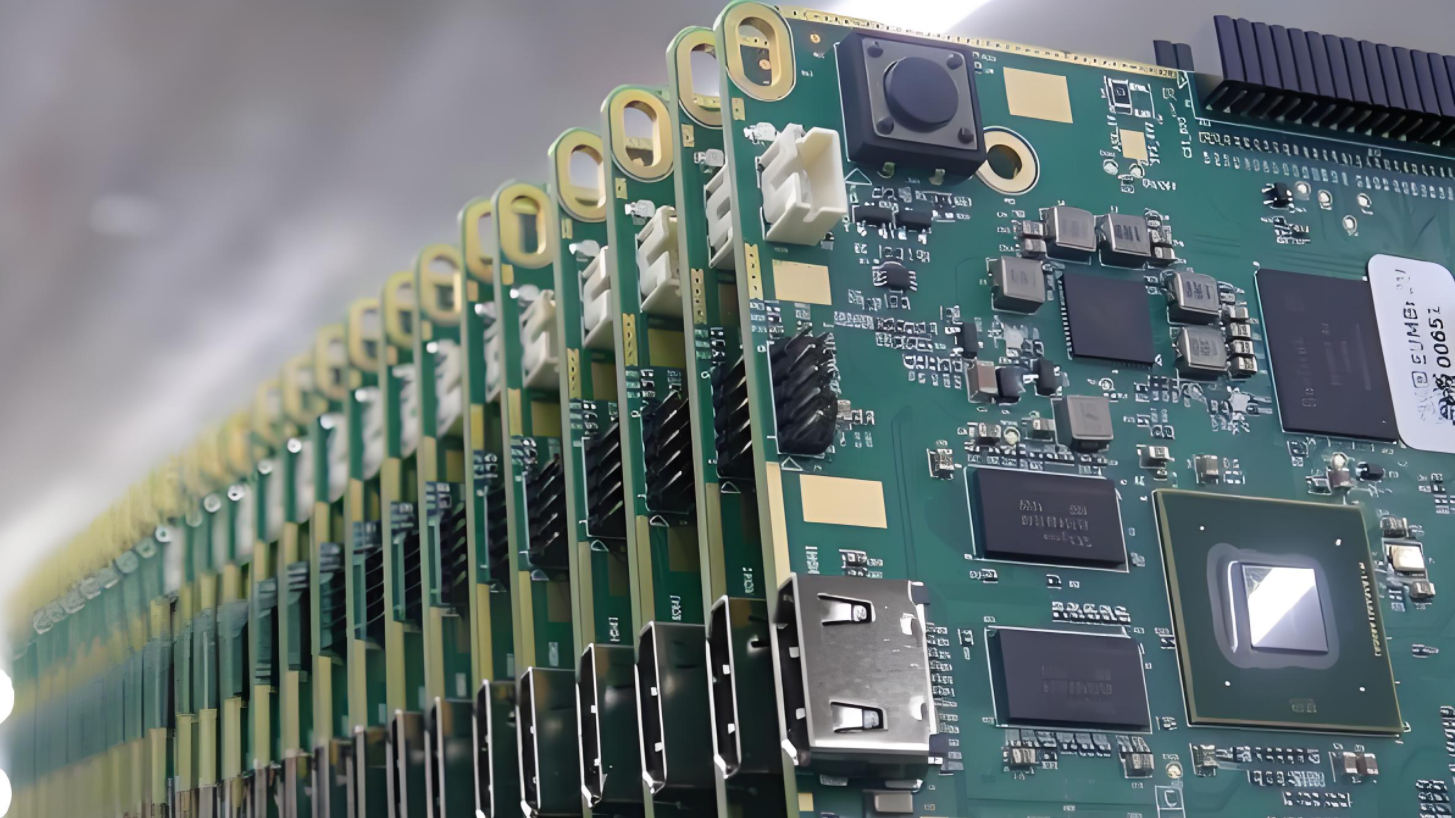

For companies seeking product assembly services in China, it is critical to understand the difference between PCB manufacturing and PCB assembly. PCB manufacturing provides the foundation for the creation of a bare circuit board, while PCB assembly breathes life into the board by integrating electronic components to form functional circuits. As a leading PCBA supplier and Chinese PCB manufacturer, New Dachang Technology excels in both aspects, providing comprehensive PCB assembly services to meet the diverse needs of customers.

In summary, the differences between PCB manufacturing and PCB assembly highlight the complex and interrelated processes in electronics manufacturing. New Dachang Technology’s expertise in PCB assembly, coupled with state-of-the-art facilities and commitment to quality, makes it a trusted partner for companies seeking reliable product assembly services in China. By understanding the nuances of PCB manufacturing and PCB assembly, businesses can make informed decisions and leverage the expertise of reputable suppliers to realize their electronic products.

As a leading PCBA supplier and Chinese PCB manufacturer, Xindachang Technology has proven the seamless integration of PCB manufacturing and PCB assembly, providing comprehensive product assembly services and one-stop PCBA solutions to meet the ever-changing needs of the electronics industry.

Post time: May-09-2024