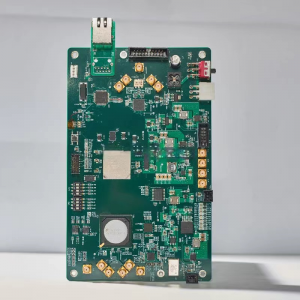

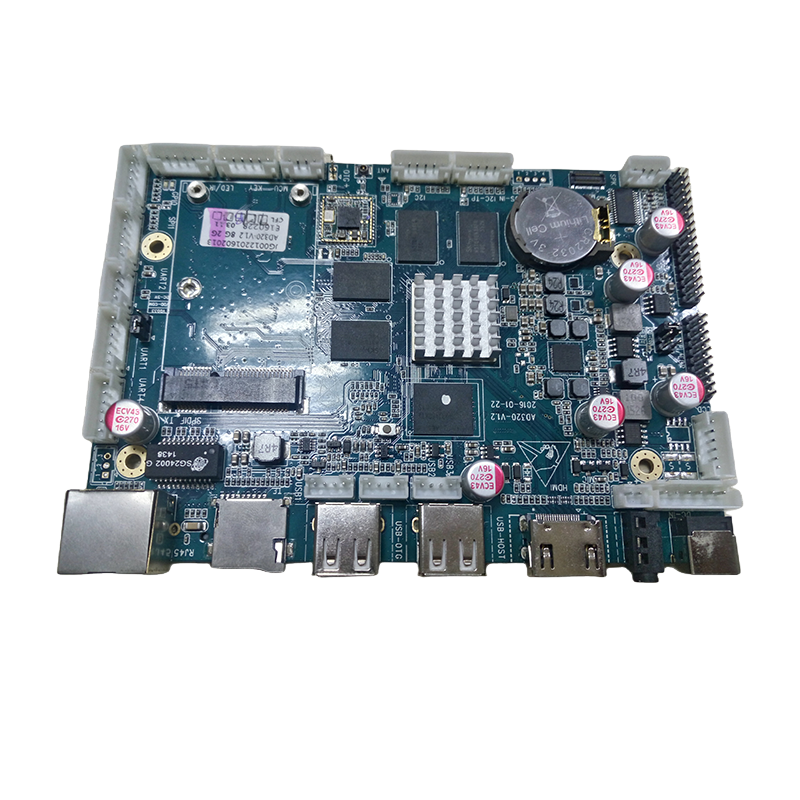

Professional custom PCB assembly electronic circuit board aerospace information PCBA board

1.Checking model,package,value,polarity etc.of each component before SMT process.

2.Confirming any potential issues with customers in advance.

FAQ

Q: What type of services do you provide ?

BEST: We provide turnkey solutions including PCB fabrication, components sourcing, SMT/DIP assembly, testing, mold injection, and other value-added services.

Q: What is required for PCB & PCBA quotation?

BEST:

1. For PCB: QTY, Gerber filesand technical requirements(material, size, surface finish treatment, copper thickness, board thickness etc).

2. For PCBA: PCB information, BOM list, Testing documents.

Q: What are the main appkication use cases of your PCB/PCBA services?

BEST: Automotive, Medical, Industry Control, IOT, Smart Home, Military, Aerospace etc.、

Q: What is your minimum order quantity (MOQ)?

BEST: No MOQ limited, sample and mass production both support.

Q:Do you keep the provider product information and design files confidential?

BEST: We are willing to sign a NDA effect by customers side local law and promising to keep customers data in high confidential level.

Q: Do you accept process materials supplied by clients?

BEST: Yes, we can provide component source, and also accept component from client.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Skype

-

Skype