The relationship between PCB cloth plate and EMC

Guide: Speaking of the difficulty of switching power supply, the PCB cloth plate problem is not very difficult, but if you want to set up a good PCB board, the switching power supply must be one of the difficulties (PCB design is not good, which may cause no matter how you debug the debugging The parameters are debugging the cloth. This is not alarmist), because there are many factors that consider PCB cloth boards, such as electrical performance, process route, security requirements, EMC effects, etc. Among the factors, electrical is the most basic, but EMC is the most difficult to touch. The progress of many projects is the EMC problem. This article will share with you the relationship between PCB cloth board and EMC from 22 directions.

- The cooked circuit can calmly perform the EMI circuit of PCB design

The impact of the circuit above on EMC can be imagined. The filters of the input end are here; the pressure -proof anti -strikes; the resistance R102 of the impact current (with relay reduction loss); The Y capacitor that is filtered with the filtering; the fuse that affects the security layout board; every device here is very important. It is necessary to carefully taste the functions and functions of each device. When the design circuit is designed, the EMC harsh level is calm and calm design, such as setting several levels of filtering, the number and location of the number of Y capacitors. The choice of voltage sensitivity size is closely related to our demand for EMC. Welcome everyone to discuss the seemingly simple EMI circuits of each component.

- 2.Circuit and EMC: (The most familiar anti -gravity topology, see which key places in the circuit contain the mechanism of EMC)

A few parts of the circuit in the figure above: the impact on EMC is very important (note that the green part is not). For example, everyone knows that the radiation of electromagnetic field radiation is space, but the basic principle is the change of magnetic flux. , That is, the corresponding ring circuit in the circuit.

The current can produce a magnetic field, which produces a stable magnetic field and cannot be transformed to the electric field. The electric field can produce a magnetic field. So be sure to pay attention to those places with switching status, that is, one of the source of EMC. Here is one of the source of EMC (one of them here, of course, there will be other aspects later), such as the dotted line circuit in the circuit, which is the opening of the switching tube to open the tube. The turbine circuit that is closed not only can the switching speed of the switch can adjust the impact on EMC, but the area of the cloth routing circuit also has an important impact! The other two loops are absorbing ring and rectifier circuit, first understand in advance, and then talk about it later.

- Third, the association between PCB design and EMC

1. The impact of the PCB loop on EMC is very important. For example, anti -main power ring circuit, if too large, the radiation will be poor.

2. The filter wiring effect, the filter is used to filter to interfere, but if the PCB has a bad wiring, the filter may lose the effect.

3. Structural parts, not well -ground design of the radiator will affect, the shielded version of the ground, etc.;

4. The sensitive part is too close to the source of interference. For example, the EMI circuit is close to the switch tube, which will inevitably lead to poor EMC and need a clear isolation area.

5. RC absorb the circuit.

6. The Y capacitor is grounded and wiring, and the position of the Y capacitor is also critical.

Let's give a small example below:

As shown in the figure in the figure above, the X -capacitor pin routing is processed internally. You can learn how to make the capacitor pink ride plug -in (using a extrusion current). In this way, the filtering effect of the X capacitor can achieve the best state.

- 4. Preparation for PCB design: (The preparation is sufficient, only the design can be designed step by step to avoid design overthrowing)

There are roughly aspects of the following aspects. It is considered that the design process will be considered. All content has nothing to do with other tutorials. It is just a summary of its own experience.

1. The size of the appearance structure, including positioning holes, air duct flow, input and output sockets, you need to match the customer system, and you also need to communicate with the customer, which is limited to high.

2. Safety certification, which kind of authentication of the product, which places do the basic insulation and climb distance, and where to strengthen the insulation and leave the slot.

3. Packaging design: Is there a special period, such as customized parts packaging preparation.

4. Selection of process routes: single -panel double panel selection, or multi -layer board, comprehensive assessment according to the principle diagram and board size, cost and other comprehensive assessments.

5. Other special requirements for customers.

Structural craftsmanship will be relatively flexible. The security regulations are still relatively fixed. What certifications do, and what security standards are, of course, there are also some security regulations that are common in many standards, but there are also some special products such as medical treatment.

In order to be dazzling, friends of the new entry -level engineer are not dazzling. Here are some common products that are common. The following is the specific cloth board requirements summarized by IEC60065. In mind the security regulations, you need to keep in mind. When you encounter specific products, you must deal with it:

1. The distance of the input fuse pads is greater than 3.0mm. The actual cloth plate is at 3.5mm (simply to climb the power climbing distance at 3.5mm before the fuse, and then climb the power at 3.0mm).

2. The security regulations before and after the rectification bridge are required to be 2.0mm, and the cloth plate is 2.5mm.

3. After rectification, the security regulations generally do not require requirements, but the high and low voltage room is left according to the actual voltage, and the habit of 400V is more than 2.0mm.

4. Safety regulations for the preliminary level are 6.4mm (electrical gap), and the climbing distance is best based on 7.6mm (note: this is related to the actual input voltage. allow) .

5. Use cold grounds in the first stage and clearly identify it; L, N identification, input AC Input logo, fuse warning logo, etc. all need to be clearly marked.

Everyone has doubts about the above, can also discuss and learn from each other.

Once again, the actual security distance is related to the actual input voltage and the working environment. The specific calculation of the table is required. The data is provided for reference only and the actual occasions are subject to the actual occasions.

- 5. PCB design security rules consider other factors

1. Understand what authentication of your products, what kind of products belong to, such as medical, communication, electricity, TV, etc., but there are many similar places.

2. The place where the security is close to the PCB cloth board, understand the characteristics of insulation, which are basic insulation, which are enhanced insulation, and different standard insulation distances are different. It is best to check the standard, and the electrical distance is calculated and the distance is climbed.

3. Focus on the security device of the product, such as the relationship between the transformer magnetism and the original deputy border.

4. The heat sink and the peripheral distance, the land connected to the radiator is different, the land is not the same, the ground is still cold, and the hot land insulation is the same.

5. Special attention to insurance distance, the strictest place is required. The distance between the fuse is consistent.

6. Y capacitor and leakage current, contact current relationship.

The follow -up will explain how to keep the distance and how to do security requirements.

- 6. Power layout of PCB design

1. First, measure the size of the PCB size and the number of devices, so as to be dense, otherwise it is tight, and it is difficult to see a piece of sparseness.

2. Modify the circuit, focusing on core devices, and the principle of key device to place the device at one time.

3. The device is vertical or horizontal. One is beautiful, and the other is to facilitate plug -in operations. Special circumstances can be considered.

4. When layout, you need to consider the wiring and place it in the most reasonable position and facilitate the follow -up line.

5. During the layout, the ring area is reduced as much as possible, and the four major ring roads will be explained in detail.

To achieve the above points, of course, it is necessary to use it flexibly, and the more reasonable layout will soon be born.

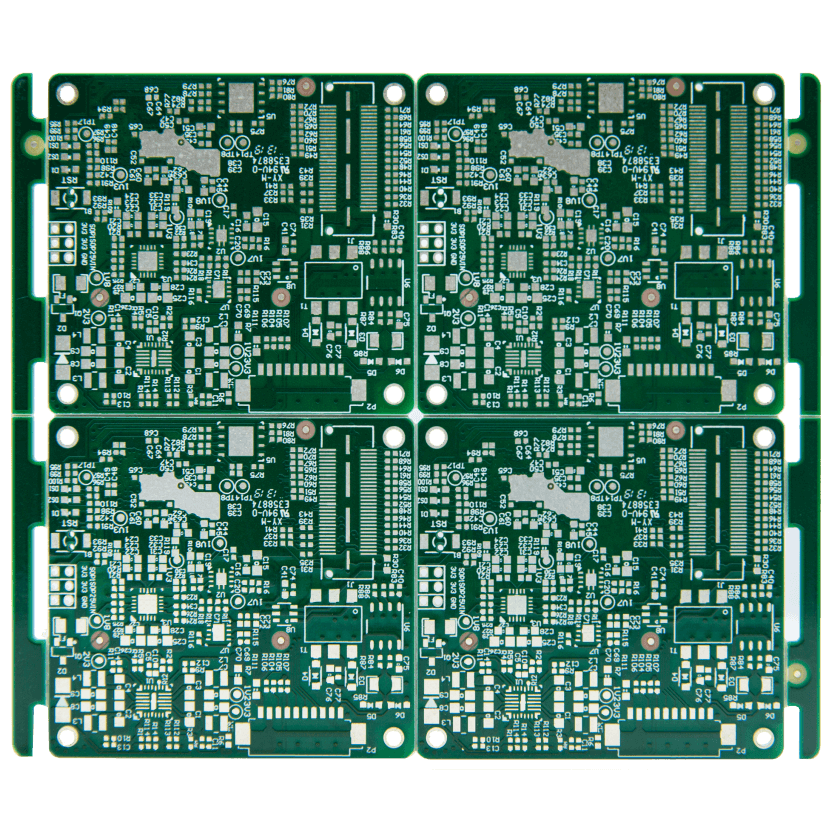

The following is a PCB board, which is worth learning from the general layout:

The power density of this figure is still relatively high. Among them, the control part of the LLC, the auxiliary source part, and the BUCK circuit drive (high -power multi -road output) are on the small board.

1. The input and output terminals are fixed and dead. Can't move. The board is rectangular. How to choose the main power flow? Here, from bottom to top, from left and right to layout, heat dissipation depends on the shell.

2. The EMI circuit is still clear. This is very important. If it is confused, it is not good to EMC.

3. The position of large capacitors should be taken into account the PFC loop and the main power loop of LLC.

4. The current of the auxiliary edge is relatively large. In order to take the current and the heat dissipation of the rectifier pipe, this layout is adopted. The rectifier pipe is on the top. just.

Each board has its own characteristics, and of course it has its own difficulties. How to solve it reasonably is the key. Can you understand the meaning of reasonable selection of layout?

- 7. PCB instance appreciation

According to the PCB layout of the previously discussed PCB layout, check this board, whether it is in place, I think it is a better place. Of course, the flaws will always be there. You can also propose it. It's not easy, you can learn from this board! Later, you will also explain and learn this board. Let's appreciate it first.

- 8. The four major ring roads of PCB design (the basic requirement of the PCB layout is the small area of the four major ring circuits)

In addition, the absorption ring (RCD absorption and RC absorption of the MOS tube, RC absorption of rectifier pipes) is also very important, and it is also a loop that generates high -frequency radiation. If you have any questions above, you are welcome to discuss it. As long as it is questioned with questions, discussing learning together can make greater progress!